N272 VIKING spreader is distinguished by its quality, robust construction and unlimited configurability.

Fill out the form and our consultant will contact you as soon as possible.

Please fill out all fields marked *.

Completing the form means that the personal data provided therein will be processed for the purpose of establishing contact. Find out who processes your data and how.

Fill out the form and our consultant will contact you as soon as possible.

Please fill out all fields marked *.

Completing the form means that the personal data provided therein will be processed for the purpose of establishing contact. Find out who processes your data and how.

Home / Products / Manure spreaders / N272 VIKING Tandem Manure Spreader

N272/3 – 14T

N272/3 – 14T  N272/6 – 18T

N272/6 – 18T

Technical GVW

20580-21020 kg

Technical load capacity

14000 kg

Cargo box capacity

13,4 m3

GVW (EU homologation)

18000*

EU homologated load capacity

13000-14800**

Capacity with 0.5m extensions

18,4 m3

Technical GVW

25680-25990 kg

Technical load capacity

18000-18510 kg

Cargo box capacity

13,4 m3

GVW (EU homologation)

18000* kg

EU homologated load capacity

12000-14400** kg

Capacity with 0.5m extensions

18,4 m3

Take a closer look

Explore the Viking from all sides with a 360o animation.

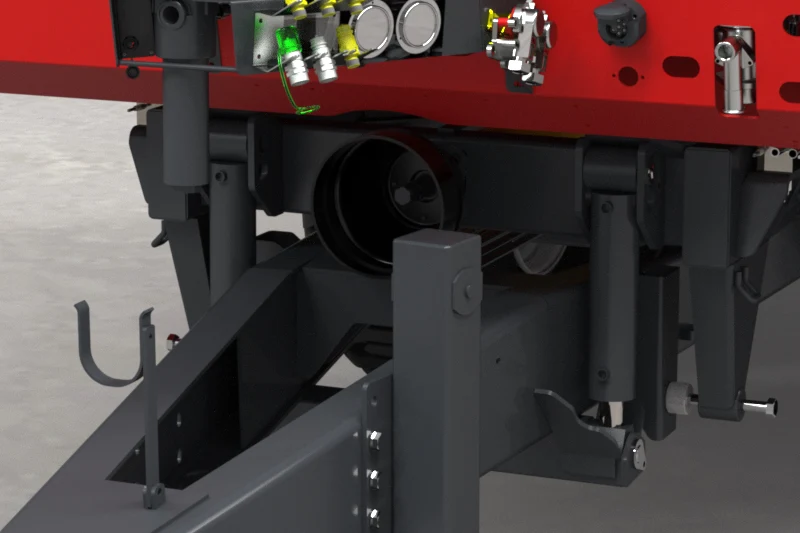

VIKING spreaders use tandem spring suspension. The 18T Viking version has a steering axle as a standard.

The hydraulically sprung hitch makes it easy to level out the entire spreader. This hitch reduces the dynamic load on the drawbar eye during operation. This improves the driving comfort when spreading manure.

The N272 Viking series spreaders are fitted with solid extensions made of 2 mm thick sheet metal, suitably reinforced with steel profiles. The side extensions can be tilted to any side, left or right, depending on which side of the spreader is used for loading. The versatility of these side extensions results from the fact that we can lower the loading height, without having to dismantle the extensions.

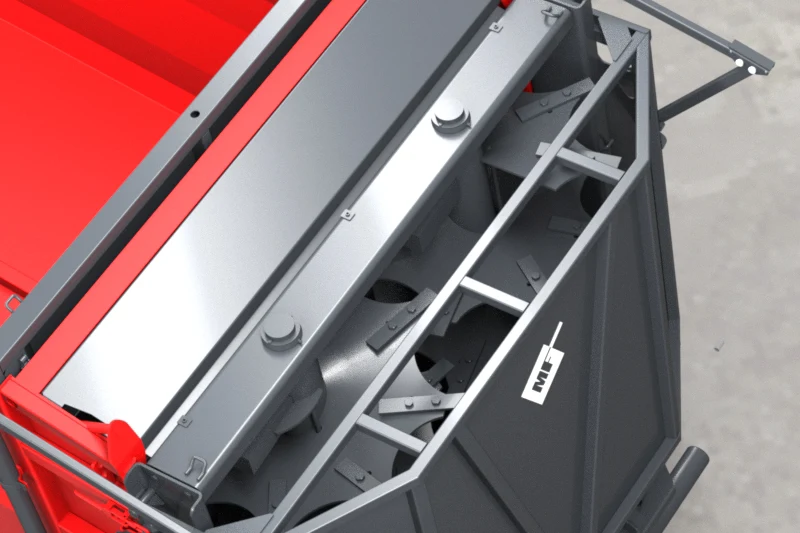

The N272 Viking manure spreader has a 2-rotor spreading adapter fitted as standard. In response to the changing needs and expectations of modern farms, we have introduced two types of adapters.

1. VERTI vertical adapter with a width of 2.0m. The main working tips are replaceable blades bolted to the rotor segments. When rotating, the rotors shred the material feed and eject it to the back and the sides. The bottom section of the rotors features bladed discs, which increase the spreading width of the material.

2. ZENI horizontal disc adapter.

On N272 Viking spreaders, a ZENI 2-rotor disc/horizontal adapter can be fitted. In its lower part there is a gearbox, on which the spreading discs and are mounted. The main working tools are interchangeable blades bolted to horizontal rotors. By rotating, the rotors grind the fed material, which is supplied by the adapter guard to the spreading discs. The rotating discs eject the shredded material backwards and sideways.

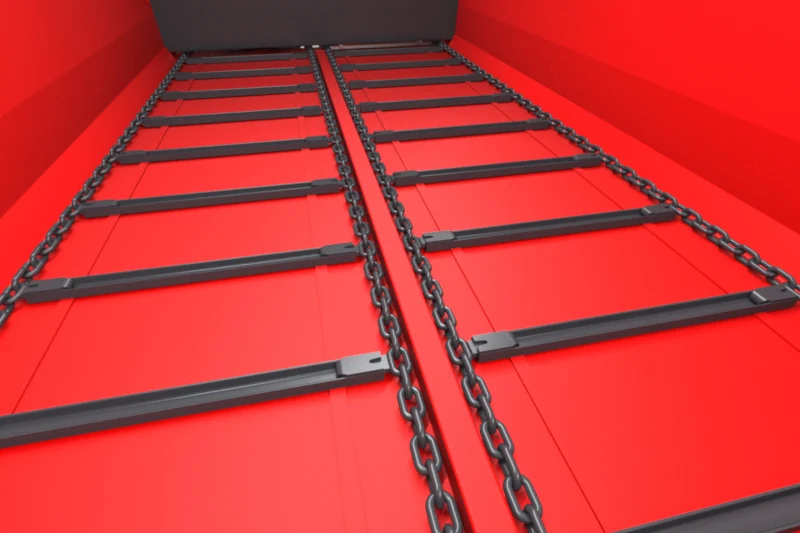

Each manure spreader features a chain floor conveyor. The speed of the floor conveyor is controlled by operating a knob on the hydraulic flow control valve. To meet the expectations of our customers, Metal-Fach has introduced electronic flow controllers operated with a control panel in the tractor cab. It is no longer required to leave the tractor to adjust the floor conveyor speed directly at the spreader.

An adaptor cover and permanently screwed side plates are fitted as standard. The side metal sheet deflectors reduce the side throw range, but their primary function is to guard the walls. Adapter cover (deflectors) lifts automatically when the rear wall (slider) is raised.

To improve the implement’s operating comfort, the Viking spreaders feature two work lights illuminating the adapter’s work area. This helps working after dark. A lamp is also located inside the shell to closely inspect the volume of material.

The N272 Viking manure spreaders feature a vertical slide gate for the load body. It protects the adapter rotors from clogging during loading, and prevents the material from falling out in transport. The slide gate can control the application rate of loose material fed to the spreading adapter in operation.

The slide gate is especially supported with the heaviest gauge at its bottom to prevent deformation by the pressure of the material against the slide gate panel and its bottom edge. The slide gate lifts to open fully over Tecamid slides to minimise friction and retain a sealed passage of loose material in transport. The slide gate bottom features a rubber strip profiled around a chain to facilitate better conformity in contact with the body floor and an improved seal.

For precise fertilisation, we offer an electronic spreading control system, which is available when connected to the ISOBUS system and/or via an external computer.

Precision farming is all about real reductions in the cost of fertilisers and plant protection products, but also:

Multiple functions in one machine? By all means

Once the spreader adapter is removed and the CARGO attachment is fitted, the VIKING spreader is transformed into a trailer for heavy loads. The trailer can be used to carry various types of crops. This gives it a versatile use on the farm and can function all year round.

The equipment shown in the photos may vary depending on the version chosen.

| Model of machine | N272/3 | N272/3 |

|---|---|---|

| Type of homologation | - | EU |

| Transport speed (max.) [km/h] | 40 | 40 |

| Technical GVW [kg] | 20580 - 21020*** | 22000* |

| GVW [kg] | 20580 - 21000*** | 18000* |

| Technical load capacity (field) [kg] | 14000 - 16500** | 14000 - 16800 |

| Transport load capacity [kg] | 14000 | 13000 - 14800** |

| Weight [kg] | 6580 - 7020*** | 6200 - 8000*** |

| Vertical load on the hitch eye (max) [kg] | 3000 | 3000 |

| Cargo box capacity (without extensions/extensions 0.5m) [m3] | 13,4 | 13,4 |

| Length / Width / Height of the cargo space [mm] | 5000 / 2000 / 1350 | 5000 / 2000 / 1350 |

| Overall dimensions without extensions Length / Width / Height [mm] **** | 7925 / 2550 / 3390 | 7925 / 2550 / 3390 |

| Height of the cargo floor from the ground [mm] **** | 1520 | 1520 |

| Loading height [mm] **** | 2870 | 2870 |

| Tires**** | 550/60-22,5” | 550/60-22,5” |

| Power requirements (min.) [KM] | 135 | 135 |

| Model of machine | N272/6 | N272/6 |

|---|---|---|

| Type of homologation | - | EU |

| Transport speed (max.) [km/h] | 40 | 40 |

| Technical GVW [kg] | 25680 - 25990*** | 24000* |

| GVW [kg] | 20500 | 18000* |

| Technical load capacity (field) [kg] | 18000 - 18510** | 18000 - 20400** |

| Transport load capacity [kg] | 12820 - 12510** | 12000 - 14400** |

| Weight [kg] | 7680 - 7990*** | 6600 - 9000*** |

| Vertical load on the hitch eye (max) [kg] | 2500 | 3000 |

| Cargo box capacity (without extensions/extensions 0.5m) [m3] | 13,4 | 13,4 |

| Length / Width / Height of the cargo space [mm] | 5000 / 2000 / 1350 | 5000 / 2000 / 1350 |

| Overall dimensions without extensions Length / Width / Height [mm] **** | 7925 / 2650 / 3495 | 7925 / 2650 / 3495 |

| Height of the cargo floor from the ground [mm] **** | 1625 | 1625 |

| Loading height [mm] **** | 2975 | 2975 |

| Tires**** | 550/60-22,5” | 550/60-22,5” |

| Power requirements (min.) [KM] | 140 | 140 |

* In European homologation, conducted according to EU Regulation 167/2013, only axle loads are specified as GVW

** The load capacity for EU homologation is calculated using the formula:

GVW + Hitch load - Tare weight = Load capacity

*** depending on the equipment

**** standard equipment

We deliver valuable and functional solutions that meet your specific needs and help you achieve better results in the field.

Fill out the form and our consultant will contact you as soon as possible.

Please fill out all fields marked *.

Completing the form means that the personal data provided therein will be processed for the purpose of establishing contact. Find out who processes your data and how.